Complete Guide to Preventing Weld Undercut: Tips and Techniques

Wiki Article

Necessary Tips for Welders: Stopping Undercut Welding and Ensuring Stronger Weld Joints

In the realm of welding, achieving durable and solid weld joints is the keystone of creating top notch work. One common challenge that welders commonly run into is undercut welding, which can jeopardize the integrity of the weld joint.

Recognizing Undercut Welding

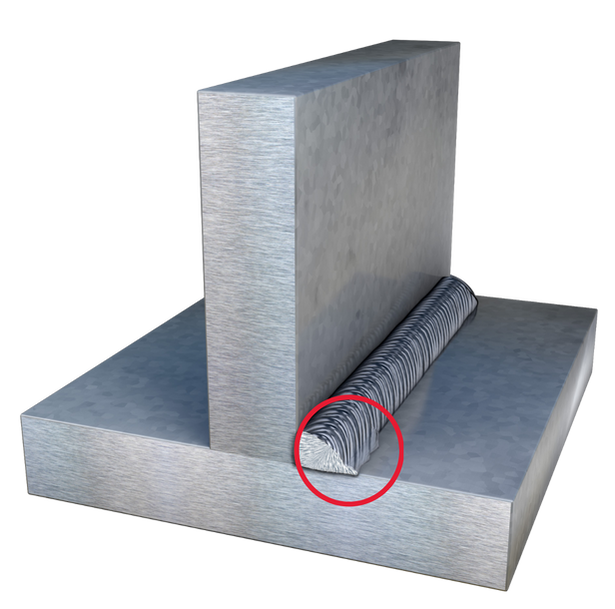

Undercut welding is a typical welding defect that takes place when the weld steel stops working to properly load the groove and leads to a groove-like anxiety along the weld bead. This defect damages the weld joint, making it vulnerable to cracking and failure under stress and anxiety. Undercutting can be brought on by numerous factors, including too much welding existing, high welding speed, incorrect electrode angle, incorrect electrode dimension, and inadequate welding technique.One of the primary factors for undercut welding is an imbalance between the welding current and the welding speed. If the welding current is expensive or the welding speed is as well quickly, the weld steel might not effectively fill up the groove, bring about undercutting. Additionally, utilizing an electrode that is as well huge can cause a comparable outcome, as the excess metal can not correctly stream into the groove.

To avoid undercut welding, welders need to guarantee they are utilizing the proper welding criteria, keep an ideal electrode angle, pick the appropriate electrode size, and practice appropriate welding strategies. By resolving these variables, welders can minimize the risk of damaging and develop stronger, extra reliable weld joints.

Proper Welding Technique

Reliable welding method plays an essential role in ensuring the top quality and stability of weld joints. One basic element of proper welding strategy is maintaining the correct angle and distance in between the welding gun and the workpiece.Furthermore, a regular and constant hand activity is vital for creating strong and long lasting weld joints. Welders ought to go for smooth, uniform activities to guarantee also distribution of the weld product. Proper adjustment of the welding gun and filler product is also crucial to achieving ideal infiltration and fusion.

In addition, controlling the warmth input and selecting the proper welding criteria based on the product being welded are critical variables in attaining top notch welds - Preventing weld undercut. Welders need to comply with the suggested settings offered by welding treatment requirements and adjust them as needed based upon the specific needs of the project. By grasping correct welding strategies, welders can considerably improve the toughness and integrity of their weld joints

Picking the Right Electrode

When taking into consideration the relevance of choosing the right electrode in welding applications,Maintaining the proper angle and distance between the welding gun and the work surface is fundamental. The choice of electrode plays a vital duty in figuring out the high quality and stamina of the weld joint. Electrodes can be found in numerous kinds, each created for certain functions and products.To start with, picking the ideal electrode size is crucial. Thinner electrodes are ideal for welding slim products, while thicker electrodes are better for thicker materials and greater warmth applications. Matching the electrode size to the density of the workpiece helps attain a balanced weld.

Secondly, understanding the product make-up of the electrode is essential. Various electrodes are created for welding specific materials like steel, stainless-steel, light weight aluminum, or cast iron. Utilizing the appropriate electrode material ensures excellent fusion and minimizes the risk of flaws in the weld.

Finally, considering the welding placement and strategy is vital when choosing the electrode type. Certain electrodes are much better site here fit for vertical or above welding settings, while others work well for level or horizontal placements. Selecting the right electrode based upon the welding method boosts the general weld quality and honesty.

Preparing the Base Metal

To make certain a successful welding procedure, what initial actions should be taken when preparing the base metal for welding? Properly preparing the base metal is essential for attaining solid and long lasting weld joints. The very first step in preparing the base steel is to clean it completely to remove any impurities such as rust, dust, paint, or oil. This can be done utilizing a wire brush, grinder, or chemical solvents. Furthermore, any existing weld material or deposit from previous welding should be removed to guarantee a clean surface for the brand-new weld.

Performing Post-Weld Assessments

After conducting these evaluations, welders should compare the results versus industry criteria and project demands to guarantee that the weld joint meets you could look here all necessary standards. Any type of insufficiencies or inconsistencies found during the post-weld evaluation should be without delay resolved with appropriate rehabilitative procedures to guarantee the weld's honesty. By vigilantly performing post-weld examinations and immediately addressing any kind of issues, welders can promote the high quality and reliability of their job, ultimately contributing to the safety and durability of the bonded structures.

Verdict

To conclude, protecting against undercut welding and guaranteeing more powerful weld joints require a combination of correct welding method, picking the best electrode, preparing the base steel correctly, and carrying out post-weld examinations. By comprehending the root causes of undercut welding and applying the required preventative measures, welders can produce top notch weld joints that meet market requirements and make certain the structural stability of the bonded elements.

Undercut welding is an usual welding problem that happens when the weld steel falls short to correctly fill up the groove and results in a top article groove-like clinical depression along the weld bead (Preventing weld undercut). Undercutting can be triggered by different aspects, consisting of excessive welding current, high welding speed, incorrect electrode angle, wrong electrode dimension, and inadequate welding technique

One of the main factors for undercut welding is an inequality in between the welding current and the welding speed. If the welding current is as well high or the welding rate is as well quickly, the weld steel might not sufficiently load the groove, leading to damaging.Keeping the correct angle and distance between the welding weapon and the work surface is fundamental when considering the importance of choosing the right electrode in welding applications.

Report this wiki page